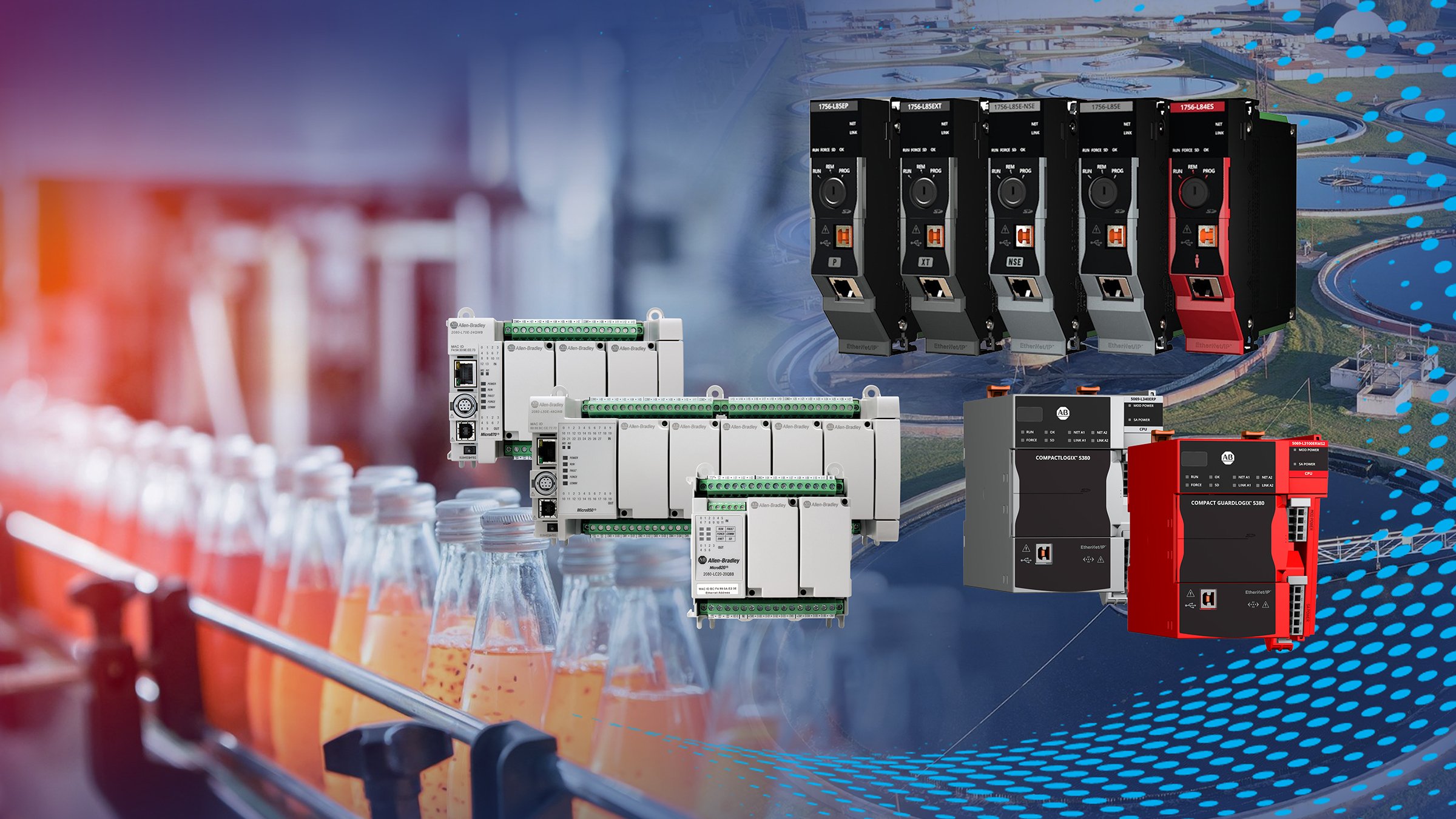

From enhancing operational efficiency to achieving tangible cost-savings, Allen-Bradley® programmable controllers can help elevate your industrial automation to new heights.

Transform your operations into a Connected Enterprise® with our smart control solutions built with scalable controllers and I/O at its core. By leveraging advanced technology and robust design, our multi-disciplined controllers enable more reliability, scalability, and flexibility to adapt to evolving market needs. Start your programmable logic controller (PLC) and programmable automation controller (PAC) selection here.